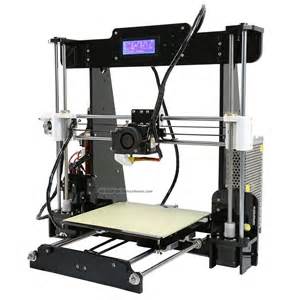

Anet A8 RepRap Prusa I3 (klon)

I have been looking high and low for a 3D printer, I chose a Prusa I3 clone, and a bit by chance it was the Anet A8 version, there are several variants to choose from. But since it with freight, VAT and taxes could be bought for approx. 1800 DKK.

It was relatively easy to assemble, you follow a YouTube guide, and with a little reel back and forth, as well as a few breaks, it was ready for print in one afternoon. Only afterwards did I find the Facebook group.

I chose not to use the included PLA, but instead ordered locally so I was "sure" of the quality, as it is certainly not everyone who praises the purity / quality of the supplied filament. And I have PT only been satisfied.

Help and instructions

Facebook grupe

YouTube guide

RepRapWIKI

If you have a 3D printer, or access to one, you can choose to print the plastic pieces for a new printer, or if there are upgrades or mods, you can deliver the pieces yourself, which can be found on thingiverse.com if you do not choose to draw yourself. them.

On the variant I have, you can choose to upgrade end stops, on the X, Y and Z axes, from mechanical to optical end stops. which should be more accurate. Link

Another option is a PNP sensor, which is mounted on the extruder (print head), so you make sure that every time you "homer" the Z-axis, it always stops 0.1 mm from the heatbed (printing surface) Link.

Since the heatbed draws a large current through the controller board, it is a good idea to charge with a MOSFET so that the current is routed around the controller board. Heatbed, uses 10 Amp (220mm x 220mm) which is the max for the terminal block on the circuit board Link. Incidentally, the heater uses only 3.3 Amp.

Since I am also a bit comfortable, I have chosen to expand with TF/SD card flex extension. since my printer is a little hard to get to.

Note that TF and micro SD are the same card, TF is just the original designation.

I am working on whether I should use Octoprint or Astroprint as a print server, I have printed a webcam holder so I have the opportunity to control what I print as I can not be home all the time. In addition, the plan is to be able to disconnect the 230 V supply via the Internet if a print fails, as I see no reason to spend 11 hours on a faulty print, or automatically if there is smoke generation.

Here is another website where the 3D printer is reviewed, Here >>>, as well as a video, from someone who has used the printer for over 3 months, where he describes his thoughts and experiences with Anet A8.